Industrial-Grade Potato Frying Machine for French Fries & Potato Chips

Our potato frying machine is specifically designed for high-capacity production of crispy French fries, uniform potato chips, and other snacks (such as chicken nuggets, spring rolls, and fried peanuts). This automatic batch fryer is suitable for food factories and commercial kitchens, utilizing advanced oil-water separation technology to ensure oil freshness and minimize waste.

Key Features of the French Fry Fryer

- Oil-water separation technology – Filters food residues into the water layer to prevent oil degradation, ensuring oil cleanliness and extending its lifespan.

- Precise temperature control – Dual automatic temperature controllers independently regulate oil and water temperatures to ensure consistent frying results.

- Multiple heating options – Choose from gas, electric, or electromagnetic heating systems to accommodate your facility’s energy configuration.

- Fully automatic operation — Optional automatic stirring, feeding, and discharge systems reduce manual labor and enhance production efficiency.

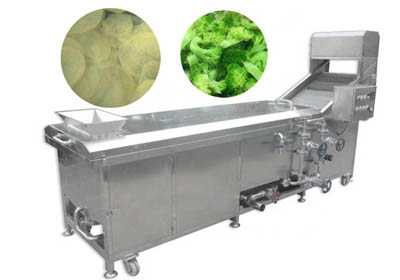

- Stainless steel construction — Corrosion-resistant, food-grade stainless steel ensures hygiene, durability, and compliance with international safety standards.

- Smoke-free and odor-free frying — An advanced cooling system eliminates oil smoke, creating a safer working environment for operators.

How the Potato Chips Frying Machine Works

The fryer’s natural air cooling system and cold water circulation system maintain optimal temperature, preventing water from boiling over. Food particles sink into the water layer and are discharged after operation, keeping the oil clean and reducing replacement frequency. This innovative technology is ideal for high-volume potato chip production lines, as oil quality directly impacts product taste and shelf life.

Applications and compatibility

- Industrial snack production: seamlessly integrates into potato chip production lines for continuous processing.

- Multi-functional frying capability: Can process banana chips, meat pies, fish slices, shrimp, vegetables, and nuts.

- Commercial use: Suitable for restaurants, hotels, and catering services requiring large-scale frying.

Customized design based on your production needs

Size, capacity, and heating methods can be customized according to your facility requirements. Whether you need compact equipment suitable for startups or heavy-duty French fries frying machines for industrial-scale production, we offer flexible solutions.

Why choose Huayuan as your food machinery partner?

As a leading food processing equipment manufacturer, Huayuan provides reliable, high-performance machinery trusted by customers worldwide. Our potato chips frying machines are exported to countries such as India, Russia, Vietnam, and South Africa, meeting ISO quality and efficiency standards.

Global presence, local support:

- Over 15 years of experience in snack production line engineering.

- Dedicated after-sales service, including installation guidance and maintenance training.

- Competitive pricing, direct factory supply.

Upgrade your snack production with our potato chip production line equipment! Contact us today for a customized quote or to request an on-site demonstration.